Make every product with care

Weather protection: Sponge Dock Shelter shield goods and workers from rain, snow, and harsh sunlight during the loading process.

Versatility: They can be easily set up and moved to different locations, accommodating various loading and unloading needs.

Increased productivity: These tents provide a covered area for continuous loading and unloading operations, even in inclement weather conditions.

Safety: They offer a safer working environment by reducing slip hazards and protecting against outdoor elements.

Cost-effectiveness: Loading and unloading tents help to minimize weather-related delays and damage to goods, saving time and money in the long run.

|

Product Name |

SEPPES Sponge Dock Shelter |

|

Produce Place |

Made in China |

|

Function |

High-sealing and high-insulation objects between the truck and the door frame |

|

Size |

3.4X3.4M customized according to customer requirements (Fixed truck model) |

|

Suitable Truck |

Cold chain truck |

|

Color |

Black |

|

Material |

Pvc fabric +sponge |

Make every product with care

Built with a strong, reinforcing aluminum frame for durability.

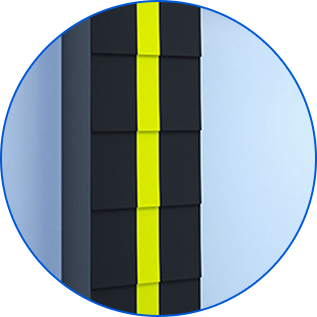

Includes reflective strips for high visibility, helping guide trucks safely.

Uses durable, weather-resistant PVC fabric for the main sealing curtains

Curtain openings are designed for effective sealing around the truck.

Available in custom sizes to fit various door dimensions.

Different models are available to suit various application needs.

● Manufacturing and processing plants

● Warehouses and distribution centers

● Cold storage facilities

● Cleanrooms and pharmaceutical facilities

● Food processing plants

● Automotive workshops

● Retail and commercial facilities

● Waste management and recycling centers

● Airports and public transport hubs

Energy Efficiency: By creating a tight seal between the loading dock and the trailer, sponge dock shelters help to minimize energy loss. They prevent conditioned air from escaping the facility and prevent outside air from entering, which reduces the workload on heating and cooling systems and lowers energy costs.

Temperature Control: Maintaining consistent temperatures inside the facility is crucial for preserving the quality of goods and ensuring worker comfort. Sponge dock shelters help to prevent temperature fluctuations by sealing the gap between the dock and the trailer, thereby preserving the indoor climate.

Contamination Prevention: Sponge dock shelters act as a barrier against dust, insects, pests, and other contaminants from entering the facility. This helps to maintain cleanliness and hygiene standards, especially in industries such as food processing, pharmaceuticals, and logistics.

Improved Safety: By reducing the risk of slips, trips, and falls caused by uneven surfaces or inclement weather at the loading dock, sponge dock shelters contribute to a safer working environment for dock workers and truck drivers.

SEPPES is a brand manufacturer in the industrial equipment industry. It has developed nearly 70 series of industrial high speed door, sectional door, high speed spiral door, three-in-one industrial defense doors, warehousing logistics loading dock leveler and dock shelter, cold storage insulation high speed doors and special explosion-proof industrial doors. SEPPES continues to innovate in technology in accordance with European industry standards. It has a number of product core technologies and has passed the EU CE and international authority SGS certification. The market covers the world and exports to more than 50 countries and regions.

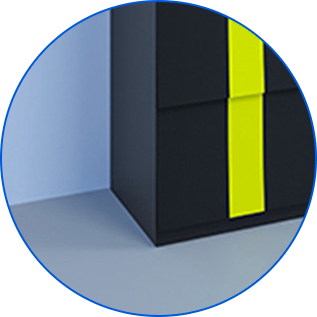

When loading and unloading goods in the factory, the truck seamlessly connected to the loading and unloading port to ensure dust-proof and damaged of goods. In this way, an ultra-affordable sponge door seal is formed to prevent dust and rain.

Reduce friction loss,perfect protection from drought, rain and wind and thus prevents energy losses.

The dock seal is equipped with sponge+ PVC-coated high-resistance fabric.

A. Configuration of trucks and trailers to be sealed.

B. Dock approach grade.

C. Size of the overhead door.

D. Dock bumper projection.

E. Dock height.

F. Dock enclosure mounting surface.

18-20 days

Project Completed

Team Members

Satisfied Clients

Total Branches