Make every product with care

Weather protection: Mechanical dock shelters provide a seal around the truck trailer, protecting goods from exposure to the elements during loading and unloading.

Energy efficiency: They help maintain indoor temperatures by preventing heat loss or gain, reducing energy costs.

Improved productivity: Mechanical dock shelters create a comfortable working environment for loading and unloading operations, enhancing productivity.

Durability: These shelters are built to withstand frequent use and harsh weather conditions, ensuring long-lasting performance.

Versatility: Mechanical dock shelters can accommodate various truck sizes and types, making them suitable for different loading dock setups.

|

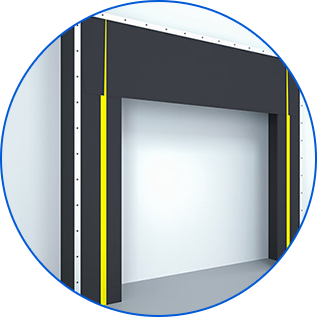

Product Name |

Mechanical Dock Shelter |

|

Feature |

Suitable more truck |

|

Function |

High-sealing and high-insulation objects between the truck and the door frame |

|

Size(mm) |

W 3400 x H 3400(customized according to customer requirements) |

|

Thickness of door curtain(mm) |

3(optional) |

|

Color |

Black(RAL9017) |

|

Material |

Polyester fabric |

|

Max Extended Force |

250 N/mm2 |

|

Friction Coefficient of Metal |

0.3 |

|

Friction Coefficient of PVC |

0.4 |

|

Diameter of Door Axis (mm) |

25 |

|

Unit Weight |

3.6kg/m2 |

Make every product with care

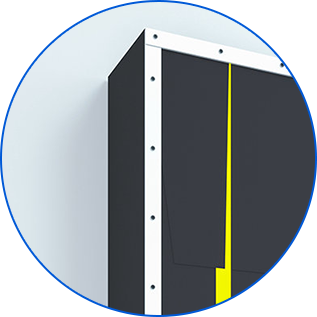

Built with a strong, reinforcing aluminum frame for durability.

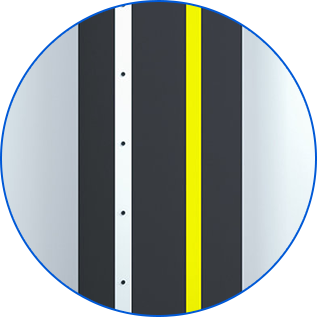

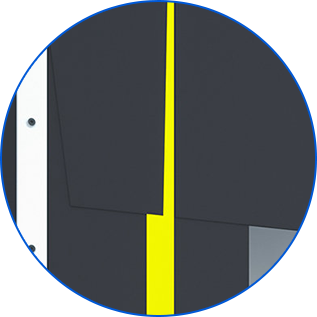

Includes reflective strips for high visibility, helping guide trucks safely.

Uses durable, weather-resistant PVC fabric for the main sealing curtains.

Curtain openings are designed for effective sealing around the truck.

Available in custom sizes to fit various door dimensions.

Different models are available to suit various application needs.

● Manufacturing and processing plants

● Warehouses and distribution centers

● Cold storage facilities

● Cleanrooms and pharmaceutical facilities

● Food processing plants

● Automotive workshops

● Retail and commercial facilities

● Waste management and recycling centers

● Airports and public transport hubs

Air Seal: Mechanical dock shelters create a tight seal around the perimeter of the trailer, minimizing the transfer of outside air, dust, insects, and other contaminants into the facility. This helps maintain a controlled environment inside the warehouse or facility, improving indoor air quality and reducing heating and cooling costs.

Energy Efficiency: By reducing air infiltration, mechanical dock shelters contribute to energy efficiency by helping to maintain consistent indoor temperatures. This can lead to lower energy consumption and operational costs, particularly in facilities with climate control requirements.

Weather Protection: Dock shelters provide protection from external elements such as wind, rain, snow, and extreme temperatures during loading and unloading operations. This helps preserve the quality of goods and ensures a safer working environment for personnel.

Worker Comfort: By creating a more comfortable working environment inside the loading area, mechanical dock shelters can improve worker productivity and morale. Workers are protected from harsh weather conditions, leading to a more pleasant and efficient working environment.

SEPPES is a brand manufacturer in the industrial equipment industry. It has developed nearly 70 series of industrial high speed door, sectional door, high speed spiral door, three-in-one industrial defense doors, warehousing logistics loading dock leveler and dock shelter, cold storage insulation high speed doors and special explosion-proof industrial doors. SEPPES continues to innovate in technology in accordance with European industry standards. It has a number of product core technologies and has passed the EU CE and international authority SGS certification. The market covers the world and exports to more than 50 countries and regions.

Loading and unloading truck fleets consisting of vehicles almost identical in width and height

Perfect protection from drought, rain and wind and thus prevents energy losses.

The dock shelter is equipped with pvc strip and aluminum profile bracket.

1. Configuration of trucks and trailers to be sealed.

2. Dock approach grade.

3. Size of the overhead door.

4. Dock bumper projection.

5. Dock height.

6. Dock enclosure mounting surface.

18-20 days

Project Completed

Team Members

Satisfied Clients

Total Branches